Critical infrastructure in an earthquake zone

The Kipoi site lies within a high-seismicity region, and GCA were commissioned to design a structure which could withstand the worst seismic event expected in a 2,475 year return period

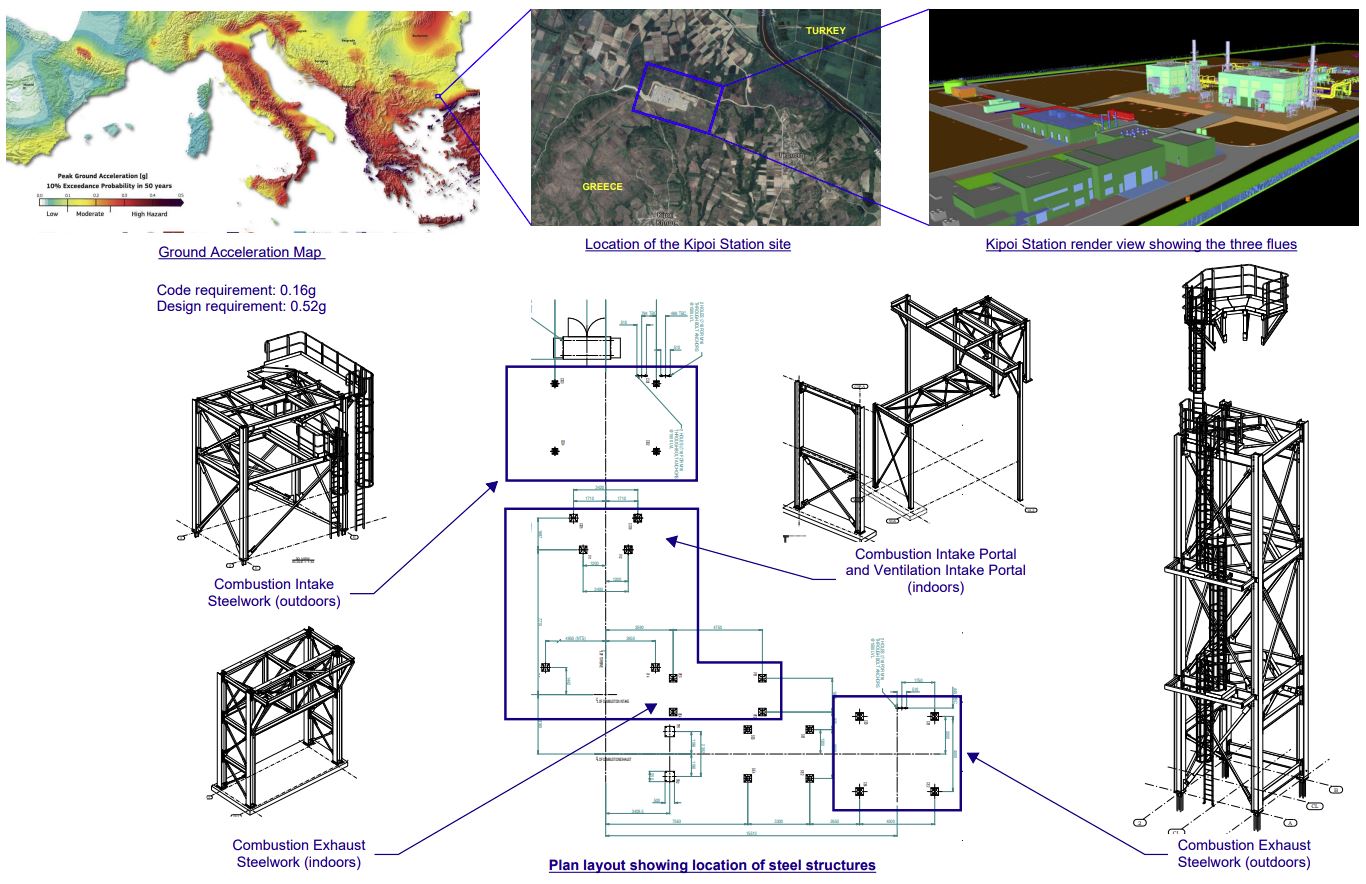

KIPOI COMPRESSOR STATION - TRANS-ADRIATIC PIPELINE (TAP)

The Trans-Adriatic Pipeline (TAP) is a natural gas pipeline nearly 900km long, currently under construction in southern Europe.

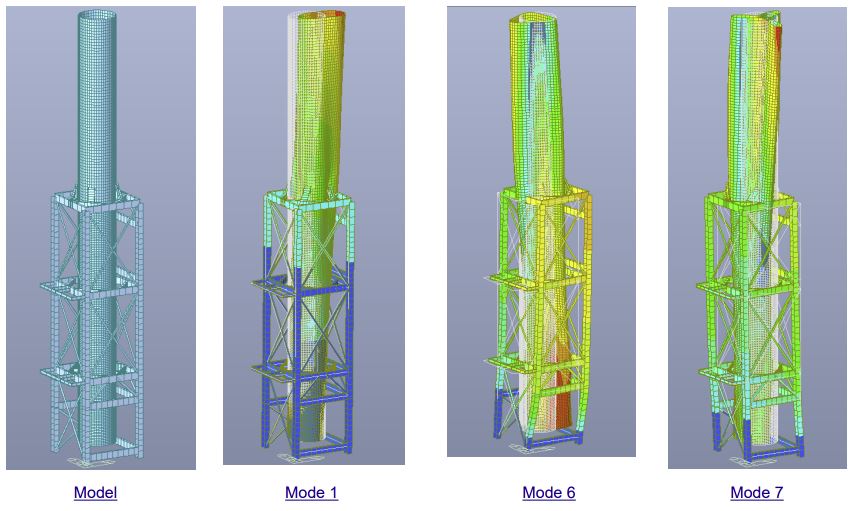

GCA Consulting was engaged by Cullum Detuners to undertake the design of five structures at the Kipoi Compressor in Northern Greece, a key part of the pipeline’s route into Europe. These structures support a ventilation exhaust, a runway beam and an oil coalescer, as well as a combustion intake filter, a ventilation intake filter and a combustion exhaust flue. The flue offered the most significant challenge, as it comprised a slender structure at over 30m high with a 4x4m footprint.

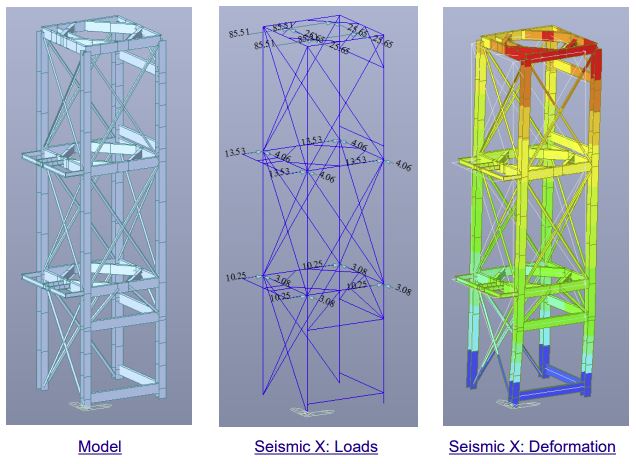

Seismic forces were calculated to exert lateral loads on the tower of 50 tonnes, and as part of critical national infrastructure the tower had to withstand such loads whilst still meeting serviceability requirements (with limited permitted deflections). The design was complicated by the requirement for open zones along its height for heat recovery and maintenance access.

Design Challenges

The Kipoi site lies within a high-seismicity region. The brief required the structure to be able to withstand a 2475-year return seismic event, which corresponds to a ground acceleration of 0.52g (3 times larger than the value stated in the Greek National Annex).

GCA rapidly developed our understanding of the requirements for seismic analysis and design within the time constraints given and delivered a structural design which met both the client’s requirements and the supply chain’s rigorous checking processes. GCA undertook thorough research into local codes and design methods, translated the Greek National Annexes in-house and developed expertise in the relevant 3D dynamic analysis methods. The acquired knowledge was directed towards producing a rigorous design, supporting the client and resolving efficiently issues that appeared during the design and construction phase.

GCA performed two methods of analysis, escalating as the project progressed from the static Lateral Force Method to full dynamic Modal Response Spectrum Analysis (MRSA) to capture the complex behaviour of the flue support towers. This enhanced the client’s confidence and ensured approval through the checking process. In addition, GCA developed a detailed analysis scope describing the methodology, assumptions and parameters used in the calculations.

This statement was issued through the supply chain to the checking engineers early in the design process to ensure the parameters for design were agreed before detailed work was undertaken, This sped up the review and checking process at the later, time critical parts of the project.

In addition to the seismic loads the outdoor structures were required to resist winds of up to 60mph and temperatures down to -20°C. GCA undertook detailed calculations of the wind effects on the unclad structures, the exposed ducting and the cylindrical flues and determined appropriate steel sub-grades for the given design temperatures.

GCA worked with numerous international stakeholders, and engaged with all involved team members to:

1. Design a significant structure to support critical infrastructure in a seismically active region.

2. Eliminate areas of ambiguity in the design brief e.g. the definition of the Importance Factor for seismic analysis.

3. Work with the full team to agree practical conclusions for the correct consequence and execution classes.

4. Be proactive in pushing the programme forward by providing options and solutions during the design and construction phase (e.g. anchoring options for the flue tower and temporary support design for installation).